What’s News?

Industrial Filters – more than just a spare part

Table of Contents

You SO Smart. Because You're Reading Why Industrial Filters are So Damn Goooood.

Yeah, alright.

I’ve got a soft spot for industrial filters.

Some of you people love beer tasting.

I prefer filter testing.

To most people, a filter looks like nothing more than a throwaway part — a bit of folded paper tucked inside a canister.

But the best filters are far more than that.

Think of them as sculptures in symmetry — rows of shiny, pleated folds designed not just for good looks, but to trap contaminants at microscopic levels.

Gives this ole gander goosebumps just thinking about it.

Behind those folds you’ll often find advanced materials.

Cellulose blended with synthetic fibres, nanofiber coatings finer than a strand of hair, and resins that hold it all together under punishing heat and pressure.

Each crease, each layer, is there for a reason readers — to maximise surface area, improve flow, and extend life.

Makes me salivate.

Far from being disposable throwaways, they’re clever little guardians that protect engines, hydraulics, and entire industries from grinding to a halt.

I digress…

Be Smart at Smoko and Know These Filter Facts...

So especially for our YOu So Smart blog series, if you want to be the sharpest thinker at smoko and teach your smart ar$e boss a thing or two (like my team does), here are a few fast facts that’ll surprise even the seasoned pros.

1. Early Cars Shipped Without Filters (And Paid the Price)

Well, there you go.

The very first Holden 48-215 didn’t come with a filter fitted as standard.

The same goes for a lot of machinery in the 1950s.

In forgiving climates, that might’ve been fine, but in the Australian bush?

Engines got “dusted” and failed quickly.

2. WWII Made Filters Smart (Junior & Senior Sizes Only)

Modern filtration owes a lot to World War II. The American military needed tough, simple solutions, so they standardised oil filters into just two sizes: Junior and Senior. Every bit of equipment was used by them. That wartime ingenuity built the foundation for today’s industry.

3. Modern Filters Catch Stuff 1/50th the Width of a Human Hair

From the outside, today’s filters still look familiar. But inside, it’s nanotech magic. Donaldson’s Ultra-Web® technology, for example, uses fibres thousands of times finer than a grain of dust. That means filters now capture particles 1/50th he width of a human hair.

4. Filters Are Now Making Mining Safer and Greener

Filters aren’t just protecting engines anymore.

In mining, massive filter presses now squeeze toxic slurry into solid, safe material that can be stacked — reducing environmental risks.

Some companies are even turning sewage sludge into biodegradable plastics.

OK now for some fun FAQs & Testers...

Q: What’s the basic function of a filter?

A: A filter is a dirt trap. It either stops external contaminants before they enter (like an air filter) or catches internal contaminants (like an oil filter). Simple, but essential.

Q: What happens if you use a cheap, low-grade filter?

A: You risk more wear and tear, reduced efficiency, higher failure rates, and bigger maintenance costs. In other words, a false economy. Don't do it.

Q: Did you know WWII gave us the first standardised oil filters?

A: The US military issued just two sizes, Junior and Senior, for everything from tanks to trucks. That standardisation kick-started the modern filtration industry.

Q: Why were early “oil bath” filters useless in Australia?

A: They were designed for the UK’s damp Midlands. In the heat and dust of the outback, engines were overwhelmed and quickly “dusted.”

Q: What’s Donaldson’s Ultra-Web® Nanofiber Technology?

A: It’s a fine nanofiber web layered with cellulose, catching particles smaller than 1 micron. That’s 1/50th the width of a human hair.

Q: Did you know filters help fight climate risks in mining?

A: Dewatering tailings into solid sacks reduces the need for risky tailings dams and recycles water. It’s a safer, greener solution.

Q: Can waste sludge really become plastic?

A: Yes — start-ups like B-Plas (backed by Diemme Filtration) are turning sewage sludge into biodegradable plastics. That’s filters enabling the circular economy.

Q: Did you know Ryco gave Australia its first spin-on filters?

A: In the 1950s, Ryco launched the Z9 and Z10. Aussie-made, mass-produced, and still part of our filter DNA.

Bonus Smoko Smarts...

- Filters are universal problem-solvers. From air, oil, and fuel, right through to hydraulics, there’s a filter for every contaminant.

- Most filters have alternatives. Even if the exact brand isn’t available, cross-referencing can get you a working equivalent fast.

- Downtime costs more than filters. Swapping cheap parts for quality ones saves engines, money, and headaches in the long run.

- Local knowledge matters. Aussie dust, heat, and humidity demand Aussie Smart when choosing the right Filter.

Visit the Filter Fanatics

At RED SHED, we’re not just selling filters - We know how to cross-match, source alternatives, and make sure you’re never left stranded waiting for one specific part number.

If your engine, compressor, or hydraulic system needs a filter, we’ll help you find the best fit — whether it’s the original brand or a smart alternative.

That’s the RED SHED difference. Smarts, service, and solutions that keep you going.

Next time someone asks what’s so special about a filter, you will be the most impressive one in the room

Jeez, I enjoyed researching all that.

Cheers - Craig

Doctor of Filtrology (with honours in Hydraulic Oil, minor in Cross-Referencing, and a lifetime thesis on “The Beauty of the Pleat”)

Listen to our latest research Deep Dive. AI-Generated audio content from factual resources. Not a bad listen!

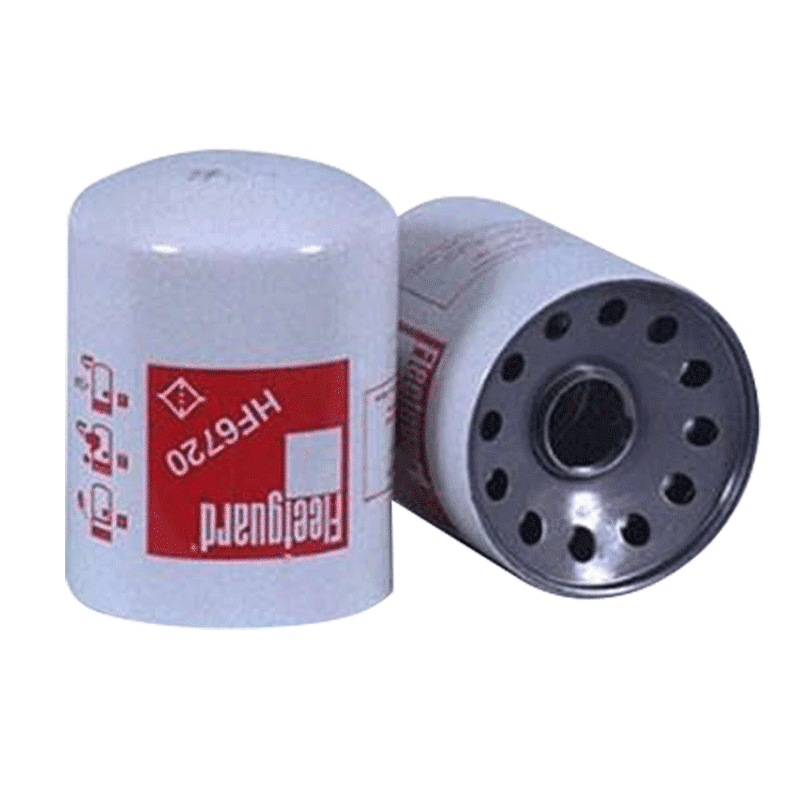

FILTERS INSTORE AT READ SHED

These are a few of our favourite things....